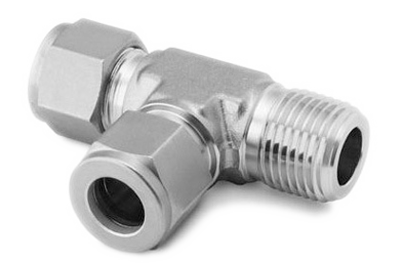

Male Run Tee Instrumentation Fitting

Product Description

Male Run Tee is used to resist mechanical pull-out which is suitable for use with thin-wall piping/tubing. These fittings mainly used in refrigeration equipment, air compressor, and machinery. They look like an English letter ‘T’ that’s why they are known as Male Run Tee.

Here at, L. V. Overseas we are manufacturing, supplying and exporting high-quality Male Run Tee Pipe Fittings that are available in various dimensions, shapes, and specifications. Our most trusted vendors supply high-quality raw products that we use to manufacture premium quality instrumentation fittings. Our comprehensive ranges of ferrule fittings are acknowledged not only in Indian as well as Overseas market.

Typical Applications

-

food and food processing industries.

-

sewage and water treatment plants.

-

risers for oil platforms and pipelines.

-

ships and marine equipment.

-

pharmaceutical industry.

Weldability

Good

Related material specifications

Bore diameter: 28mm to 900 mm. Internal Diameter Accuracy: H7,H8,H9. Internal Roughness: RA 0.1Mu m – RA 0.2Mu m.

Availability

Key features

-

Nice corrosion resistance

-

Good abrasion resistance

-

Low magnetism

-

Long working life

Corrosion Resistance

Very Good

Machinability

Good / fair.

Male Run Tee Instrumentation Fitting specifications

Pressure Ratings |

Up to 11 000 psig (760 bar), Medium-Pressure – Up to 20 000 psig (1378 bar) High-Pressure – Up to 60 000 psig (4134 bar). |

Types |

NPT, ISO/BP, SAE/MS, AN, weld ends |

Sizes |

1/16 to 2 in.; 2 to 50 mm, Medium-Pressure – 1/4, 3/8, 1/2, 9/16, 3/4, 1 in.; 6, 10, 12 mm High-Pressure – 1/8 to 9/16 in. |

Temperature Ratings |

Up to 1000°F (537°C) |

Chemical Composition (weight %)

| C | Si | Mn | P | S | Tensile strength kg/mm² |

Yield point kg/mm² |

Elongation% |

| 0.25 or less |

0.35 or less |

0.30 0.90 |

0.040 or less |

0.040 or less |

52 up | 39 up | 15 up |

| 38 up | 22 up | 30 up |

Mechanical Properties

| Grades | Delivery Conditions | Tensile Strength Rm (Mpa) | Elongation in the longitudinal direction Al (%) |

| St 45 | +A (GBK) | 390 min | 21 min |

| St 52 | +A (GBK) | 490 min | 22 min |

| E355 | +A (GBK) | 450 min | 22 min |

| 1020 | +A (GBK) | 390 min | 21 min |