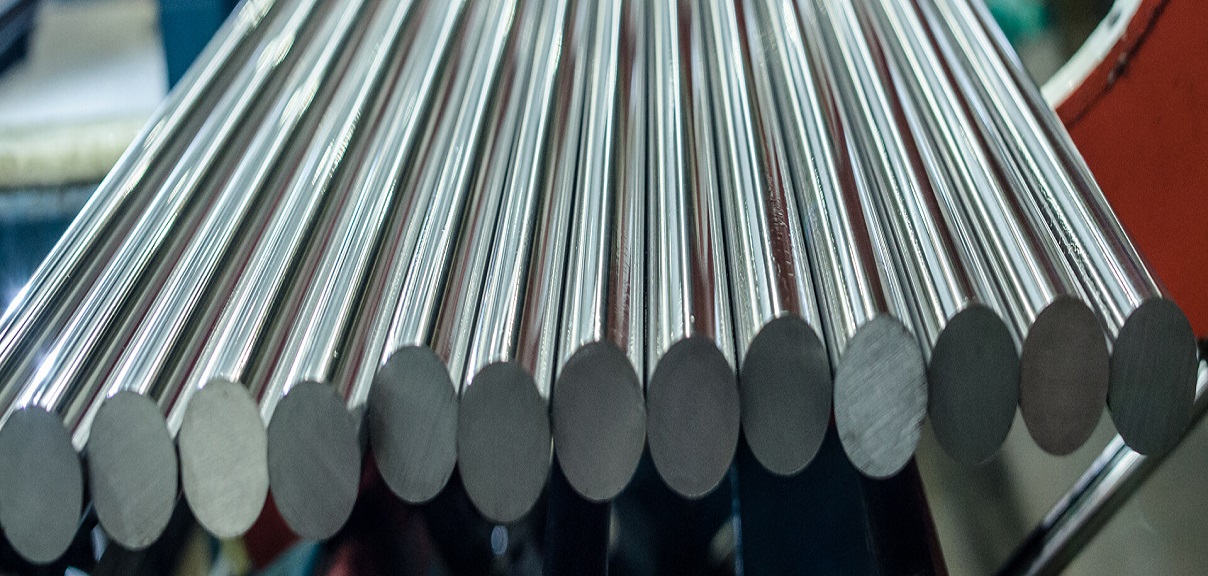

Hastelloy Round Bar

Product Description

L.V.Overseas is an industry-leading producer and manufacturer of Hastelloy C-276 Round bars. The ASTM B574 Hastelloy C276 Round Bars that we produce have developed a reputation in the industry because of the longer work life and higher durability that they offer. We at Nexus Impex produce the UNS N10276 Hastelloy Round Bars using the best quality of the raw materials available in the industry. The production process at the Nexus Impex is carried out with the modern production procedures ensuring that the Hastelloy C-276 Round bars offer high strength and stability.

L.V.Overseas is one of the famous suppliers and manufacturers of Hastelloy C 276 Round Bars, Hastelloy C276 Round Bar & Hastelloy C276 Rods, ASTM B574 Hastelloy C276 Round Bars, Hastelloy C276 ASTM B574 Bar, ASME SB 574 Hastelloy C276 Roads which is thick in the warmth treated condition at 1370 °C (2500 °F), fast extinguished, has a normal Olsen glass profundity of 0.48″. Hastelloy C-276 composite Round Bars can be fashioned, hot-disturbed, and affect expelled. Compound C276 Bars welding items are utilized as coordinating arrangement filler material for welding C276 amalgam fashioned and cast items, for unique welding applications including other nickel-chromium-molybdenum composites and stainless steels, and for weld overlay or cladding of steels. Parts that have been hot-shaped in Hastelloy C-276 combination Bars ought to be arrangement warm treated before definite creation or establishment, if conceivable. Alloy C276 Bars welding products are used as matching composition filler material for welding C276 alloy wrought and cast products, for dissimilar welding applications including other nickel-chromium-molybdenum alloys and stainless steels, and for weld overlay or cladding of steels. Parts that have been hot-formed in HASTELLOY C-276 alloy Bars should be solution heat-treated prior to final fabrication or installation, if possible.

Typical Applications

-

Processing plant for sulphuric, phosphoric and acetic acids.

-

Pulp and paper processing.

-

Components in gas scrubbing plants.

-

Seawater cooling equipment

-

Oil refinery components

-

Wires in electrostatic precipitators.

Weldability

Good

Related material specifications

Specifications : EN, DIN, JIS, ASTM, BS, ASME, AISI

Standard Specification :ASTM B574 / ASME SB574

Size :15NB to 150NB IN

Diameter :3.17mm to 350mm diameter

Length : 100 mm to 3000 mm Long & Above

Tolerance :H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

Grade :Hastelloy C276 (UNS No. N10276)

Finish :Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Surface :Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline

Application :Chemical process, Food processing, Petrochemical, Pollution control, Pulp and Paper, Refining, Waste treatment facilities

Condition :Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished.

Availability

C276/C22/B-2

Key features

-

Each bundle covered with plastic for protection against extreme weather.

-

End of Hastelloy C276 ASTM B574 Round Bar protected by plastic caps.

-

Bundles strapped with plastic strips..

-

Each radius of U-Bend tube separated by a separator.

-

Packaging list (laminated) placed with box/crate.

Cut to size capability

We can cut from one off blanks to the largest production run for immediate or just in time deliveries.

Corrosion Resistance

Very Good

Machinability

Good / fair.

Hastelloy Round Bar

specifications

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

GOST |

EN |

OR |

Hastelloy C276 |

2.4819 |

N10276 |

JIS NW 0276 |

ХН65МВУ |

NiMo16Cr15W |

ЭП760 |

Chemical Composition (weight %)

| Steel Grade | C | Mn | S | Si | Co | Ni | Cr | Fe | Mo | P |

| C276 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

| C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

| B2 | 0.02 max | 1.0 max | 0.1 max | 0.03 max | 1.0 max | Bal | 1.0 max | 2.0 max | 26 – 30 | 0.04 max |