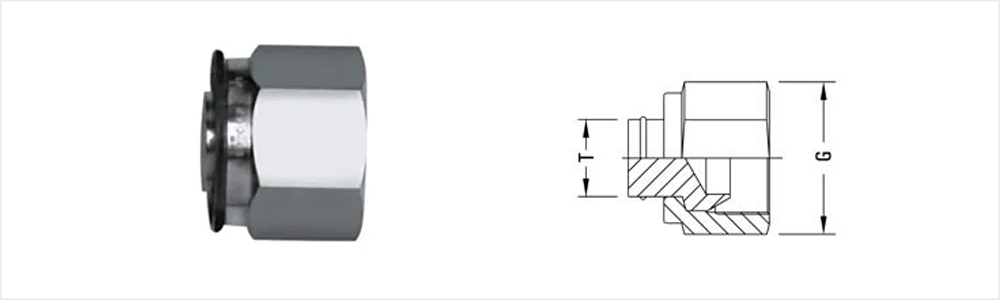

Fitting End Closure Instrumentation Fitting

Product Description

L. V. Overseas is a recognized manufacturer and supplier of Fitting End Closure, which are not designed for service in wet corrosive environments. Stainless Steel Fitting End Closure is the low carbon version of the alloy, and is operated for easiness of fabrication. Super Duplex Steel Fitting End Closure are prone to intergranular corrosion after long term exposure at high temperatures. However, due to its high chromium content (25%), these Inconel Alloy Fitting End Closure is more corrosion resistant than most heat resistant alloys. Monel Alloy Fitting End Closure has a carbon content restricted to exclude the lower end, so is the grade of choice for high temperature applications. The high chromium content of Hastelloy Alloy Fitting End Closure intends to increase high temperature properties and gives good aqueous corrosion resistance.

Nickel Alloy Fitting End Closure, Inconel Fitting End Closure Dealer, Hastelloy Fitting End Closure, Monel End Closure Fitting Distributor, Duplex Steel Fitting End Closure Stockist, Carbon Steel End Closure Compression Tube Fittings, Copper Nickel Fitting End Closure Exporter in India.

Like other austenitic grades, these Nickel Fitting End Closure have excellent toughness, even down to cryogenic temperatures, although other grades are normally used in sub-zero environments. Brass Alloy Fitting End Closure can be utilized in slightly oxidizing, nitriding, cementing and thermal cycling applications, albeit, the maximum service temperature must be reduced. The high carbon content of these Copper Nickel Fitting End Closure, which is present to enhance creep properties, has a detrimental effect on aqueous corrosion resistance. Alloy 20 Fitting End Closure can be offered in customized length sizes and shapes, and are available at market leading prices.

Typical Applications

-

food and food processing industries.

-

sewage and water treatment plants.

-

risers for oil platforms and pipelines.

-

ships and marine equipment.

-

pharmaceutical industry.

Weldability

Good

Availability

Key features

-

Nice corrosion resistance

-

Good abrasion resistance

-

Low magnetism

-

Long working life

Corrosion Resistance

Very Good

Machinability

Good / fair.

Fitting End Closure Instrumentation Fitting specifications

Imperial Size |

1/2″ to 2″ |

Dimensional Standard |

ASME / ANSI B 16.9 |

Tube Size |

1/16”OD to 2”OD, 2mm OD to 50mm ODe |

Thread |

NPT, BSP, BSPT, UNF, ISO, SAE, MS, AN, weld ends etc. |

Pressure Rating |

6000PSI for Stainless Steel, 300/1000/3000PSI for Brass |

Temperature Ratings |

Up to 1000°F (537°C) |

Chemical Composition (weight %)

| C | Si | Mn | P | S | Tensile strength kg/mm² |

Yield point kg/mm² |

Elongation% |

| 0.25 or less |

0.35 or less |

0.30 0.90 |

0.040 or less |

0.040 or less |

52 up | 39 up | 15 up |

| 38 up | 22 up | 30 up |

Mechanical Properties

| Grades | Delivery Conditions | Tensile Strength Rm (Mpa) | Elongation in the longitudinal direction Al (%) |

| St 45 | +A (GBK) | 390 min | 21 min |

| St 52 | +A (GBK) | 490 min | 22 min |

| E355 | +A (GBK) | 450 min | 22 min |

| 1020 | +A (GBK) | 390 min | 21 min |