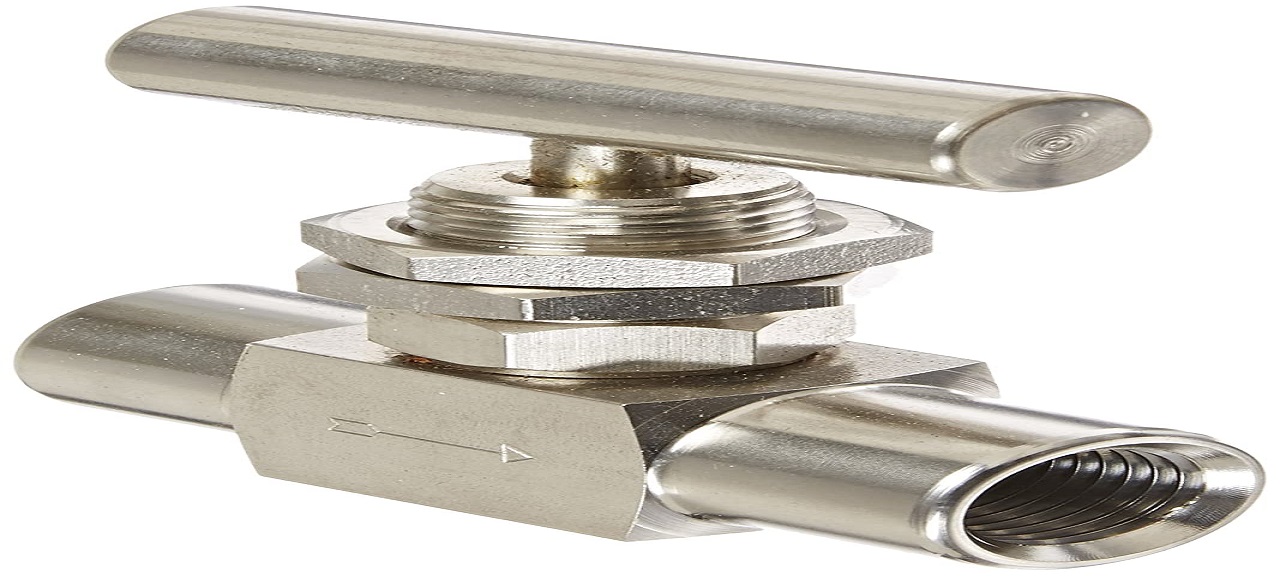

Female Needle Valves

Product Description

L. V. Overseas needle valves provide metal to metal seating and small bore isolation valve for many applications without having to resort to larger and more expensive globe valves.

The needle valve is supplied as standard with a non rotating tip to allow linear closure while eliminating galling.

L. V. Overseas standard needle valves are rated to 413bar (6,000psi), but can be rated at 689bar (10,000psi). Standard Temperature range from 240 Deg C up to 540 Deg C.

All NPT connection threads are Single Point CNC machined.

All L. V. Overseas products have material traceability and pressure test certificates to BS EN 10204 3.1. A unique code is stamped on all valve bodies linking them to their material and chemical analysis certificates.

Tips are ‘interchangeable’ without special tools or spindle changes in options of hard, soft and metering tips.

Safety – spindles are ‘back seating’ and ‘anti-blowout’ as standard, a major safety feature. Also ‘anti-removable’ steel pin is fitted into body so that head unit cannot be removed inadvertently.

Dust cap protects spindle threads from ingress of dirt and is colour coded for particular service.

Typical Applications

-

Zoological sciences

-

Gas and liquid dispensation

-

Instrumentation control

-

Cooling

-

Power generation

Weldability

Good

Cut to size capability

-

Maximum Working Pressure rating: 60,000psig (4,140bar) @72 F°(22 C°)

■ Temperature rating: 0 to 450 F°(-17.8 to 232 C°) with Teflon packing and up to 1200 F°(648 C°) with optional grafoil packing.

Availability

V Series Needle Valves

Key features

Choice of three stem types:

R-Stem – All metal, blunt stem tip

N-Stem – All metal, tapered needle stem tip

K-Stem – PCTFE stem tip Differential hardness between the strain hardened stem and cold formed body threads

provides improved cycle life

Choice of PTFE packing or elastomeric O-ring

stem seals

Cut to size capability

We can cut from one off blanks to the largest production run for immediate or just in time deliveries.

Corrosion Resistance

Very Good

Machinability

Good / fair.

Chemical Composition (weight %)

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

All information in our datasheet is based on approximate testing and is stated to the best of our knowledge and belief. It is presented apart from contractual obligations and does not constitute any guarantee of properties or of processing or application possibilities in individual cases.