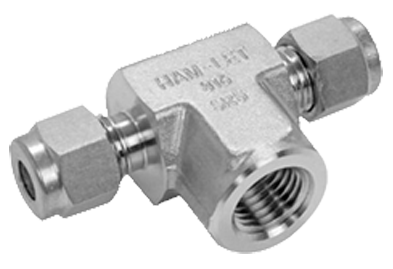

Female Branch Tee Instrumentation Fitting

Product Description

Most Eminent Female Branch Tee Pipe Fitting Manufacturer, Female Branch Tee Instrumentation Pipe Fitting, Female Branch Tee Connector, Female Branch Tee Stockist, Female Branch Tee Adapter, Female Branch Tee Tubing, Female Branch Tee with Ferrule Fittings Supplier

Stainless Steel Female Branch Tee Fittings Stockist, Carbon Steel Female Branch Tee Pipe Fittings, Nickel Alloy Female Branch Tee Fittings, Alloy Steel Female Branch Tee Pipes Fittings Exporter

We at L. V. Overseas are the most eminent Stockist, Supplier, and Exporter of superior grade high-quality Female Branch Tee Pipe Fittings. Our modern manufacturing unit has modern machinery and we use high-quality raw materials that are supplied by our most trusted vendors. We are expertizing in the manufacturing of all types of instrumentation fittings but Female Branch Tee is our specialty.

Female Branch Tee is used to connect three pipes/tubes that are right-angled and forms the T section. There is one supply line and the other two are delivery lines have an inner thread which is used to form a connection between pipes/tubes and female branch tee.

Typical Applications

-

food and food processing industries.

-

sewage and water treatment plants.

-

risers for oil platforms and pipelines.

-

ships and marine equipment.

-

pharmaceutical industry.

Weldability

Good

Female Branch Tee Instrumentation Fitting specifications

Tube OD |

1/4″

|

|---|---|

Weight |

0.14 lb |

Optional Package/Box Quantity |

5 |

Material |

316 Stainless Steel

|

Female Thread |

NPT

|

Temperature Range |

-325°F to 1200°F (-198°C to 648°C)

|

Female Thread Size |

1/4″-18

|

Availability

Key features

-

Nice corrosion resistance

-

Good abrasion resistance

-

Low magnetism

-

Long working life

Cut to size capability

We can cut from one off blanks to the largest production run for immediate or just in time deliveries.

Corrosion Resistance

Very Good

Machinability

Good / fair.

Chemical Composition (weight %)

| C | Si | Mn | P | S | Tensile strength kg/mm² |

Yield point kg/mm² |

Elongation% |

| 0.25 or less |

0.35 or less |

0.30 0.90 |

0.040 or less |

0.040 or less |

52 up | 39 up | 15 up |

| 38 up | 22 up | 30 up |