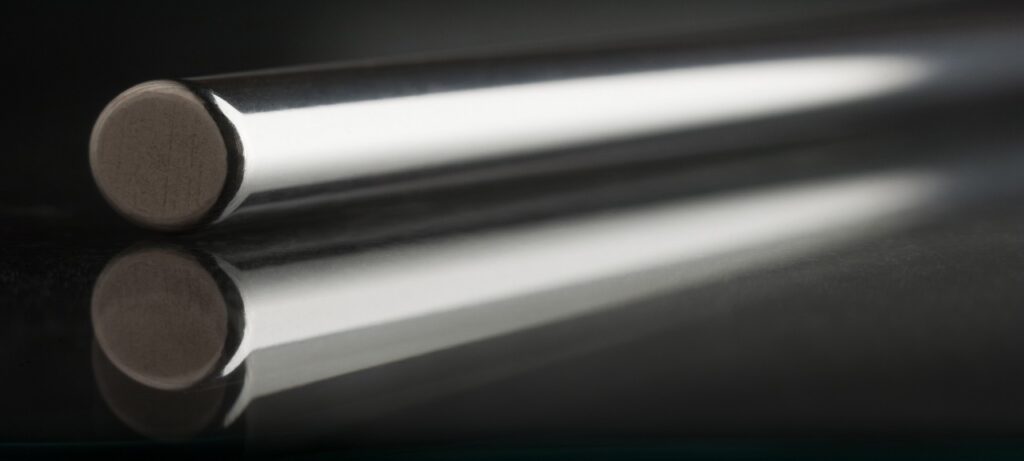

Chrome Bar

Product Description

L.V.Overseas is a manufacturer, supplier, exporter of a huge variety of products. We are an esteemed company that is pretty much engaged in giving a widespread variety of Hard Chrome Plated Bars. Being ISO certified company and producing huge range of products, we have a huge number of domestic as well as international clients. We have supplied Hard Chrome Plated Bars to clients in India as well as across the globe in countries such as US, UK, Italy, Germany, Australia etc.

We offer Hard Chrome Plated Bars at economical price to our consumers. These products have a widespread application in number of industries like sugar, nuclear, marine, defence, fabrication etc.

Depending on the terrain where the Cromax- grounded hydraulic element is going to be used, also there are different situations of erosion resistance to meet the challenge. The standard Cromax products as indicated in the folder have one chrome subcaste and are delivered wax polished. To enhance Erosion resistance in more demanding and aggressive surroundings, Cromax C and Ni-Cromax should be used. Cromax C and Ni-Cromax can be produced in all the Cromax grades.

Typical Applications

-

food and food processing industries.

-

sewage and water treatment plants.

-

risers for oil platforms and pipelines.

-

ships and marine equipment.

-

pharmaceutical industry.

Weldability

Good

Related material specifications

Good

Stainless Steel Seamless Honed Tube specifications

Material : EN8D/C45 & Other material can be used as per Customer Requirement.

Size Range : 12 MM To 150 MM (Above 150 MM can be made as per customer design & specification)

Maximum Length : Up to 7000 MM

Hard Chrome Plating Thickness : 25 To 30 Microns

Surface Finish : RA0.1µm – RA0.4 µm

Availability

-

Piston Rod

-

Hollow shaft

-

Chrome Bar

-

Induction Hardened Bar

Key features

-

High tensile strength

-

Non-corrosive

-

Elevated durability

-

Robustness

Cut to size capability

We can cut from one off blanks to the largest production run for immediate or just in time deliveries.

Corrosion Resistance

Very Good

Machinability

Good / fair.

Chemical Composition (weight %)

| Symbol | C | Si | Mn | P | S |

| Chrome Bar | 0.42 – 0.48 | 0.15 – 0.35 | 0.60 – 0.70 | 0.030 Below | 0.024 Below or less |