Manifold Valve

Product Description

Manifolds are instruments that come with one or more valves, which can be connected to a transmitter. There are some specially designed manifolds to be mounted to a pressure transmitter. They are mostly made of stainless steel, carbon steel, or alloys. Manifolds can be a perfect alternative to multivalve systems. Manifolds are widely used in sectors such as oil & gas, chemicals, wastewater, power, and so on. They help measure static, variable, gauge, and differential pressures. There are a variety of manifold valves you can buy at The Transmitter Shop.

Types Of Valve Manifold

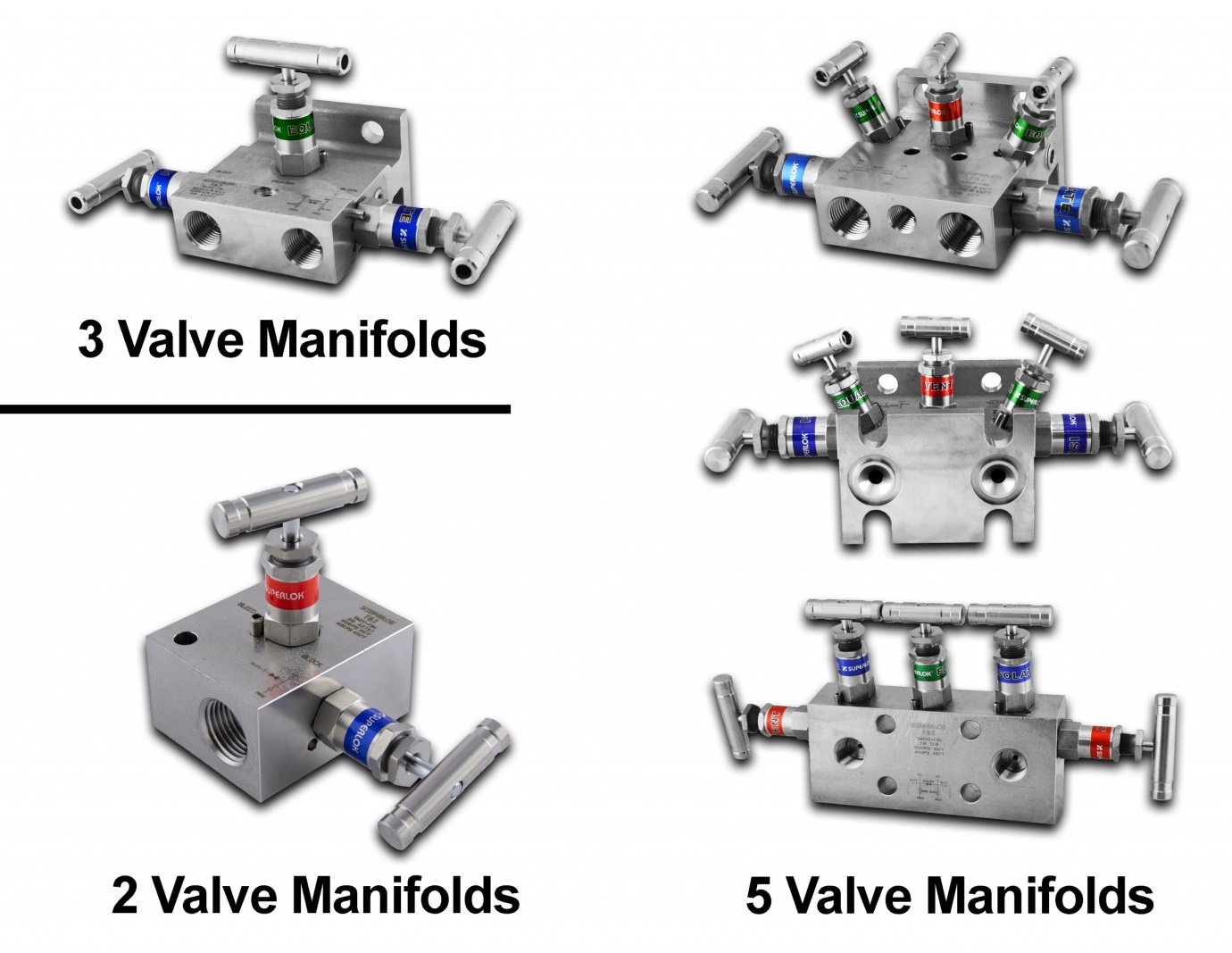

There are three types of valve manifolds:

2-way valve manifold

3-way valve manifold

5-way valve manifold

Typical Applications

Manifold valves are used with most pressure or differential pressure instruments such as gauges, switches, transducers, and transmitters. It is important to strategically select the most beneficial manifold valve for the specific application. Air, Gas, Liquid, Steam , Oil / Fuel, Medical / Pharmaceutical and Food Processing

Weldability

Good

Related material specifications

Connection : 1/2″ Female NPT to 1/2″ Female NPT.

One-piece, high strength body construction for safety no welding used.

316 stainless steel construction for superior corrosion resistance.

Bonnet lock pin prevents accidental valve disassembly.

2-1/8″ (54mm) Port centerline dimension for proper alignment.

100% pressure tested for shut-off and at all seals.

Availability

SS 316, SS 304, SS 316 TI, COPPER, BRASS, DUPLEX, CS, INCONEL, SUPER DUPLEX, HASTELLOY, MONEL, ALLOY 20, SMO 254, 904L, TITANIUM & ALL OTHER ALLOYS

Key features

Valve manifolds can be useful in many situations, from small mobile machines to heavy industrial plants. Centering any fluid power system, valve manifolds improve efficiency and reduce energy costs. Here are a few more benefits of valve manifolds:

Increased energy efficiency with shorter flow paths that minimize pressure drop and heat.

Reduced installation costs and fluid connections due to a simpler compact design.

Reduced oil leaks and upkeep with fewer connections that can fatigue, wear and loosen. Small and compact sizes with cartridge valve design to suit confined spaces.

Improved overall layout with less cumbersome hoses and fluid connections.

Corrosion Resistance

Very Good

Machinability

Good / fair.

Chemical Composition (weight %)

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |